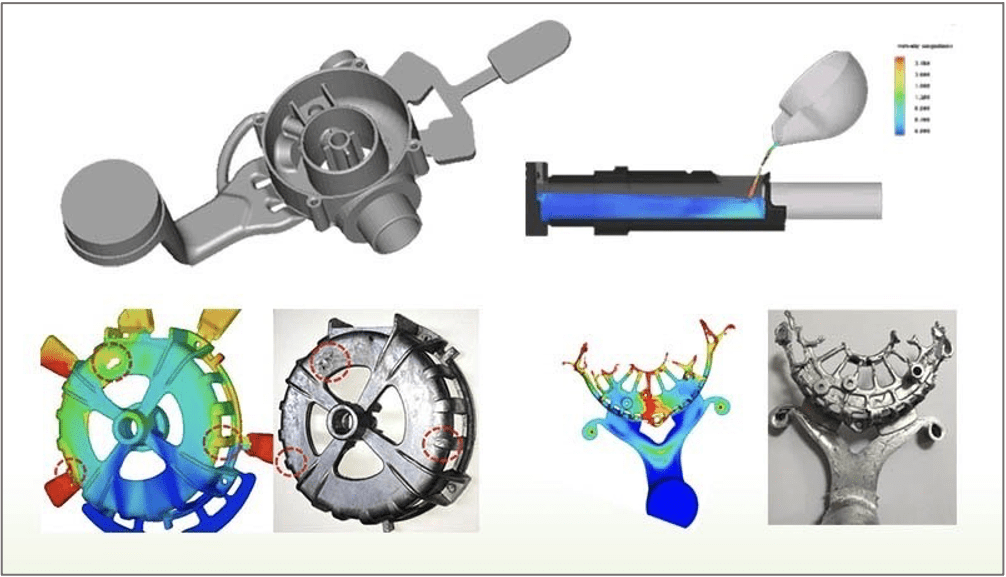

With casting simulation, you can simulate and visualize the entire casting process, starting from pouring path, filling time, solidification and also shrinkage formation.

We will simulate one cycle of your casting process includes :

- Shot sleeve simulation and comparison.

- Air tracing for blow hole and hot spot analyze.

- Temperature with filling path.

- Shrinkage formation.

- Solidification.

Benefits of Casting Simulation

- Predicting the possibilities of defects.

- Analysing the design of part, to minimize errors design while developing new part.

- Improving quality of part.

- Indicating areas in the casting part, that might have shringkage or porosities.