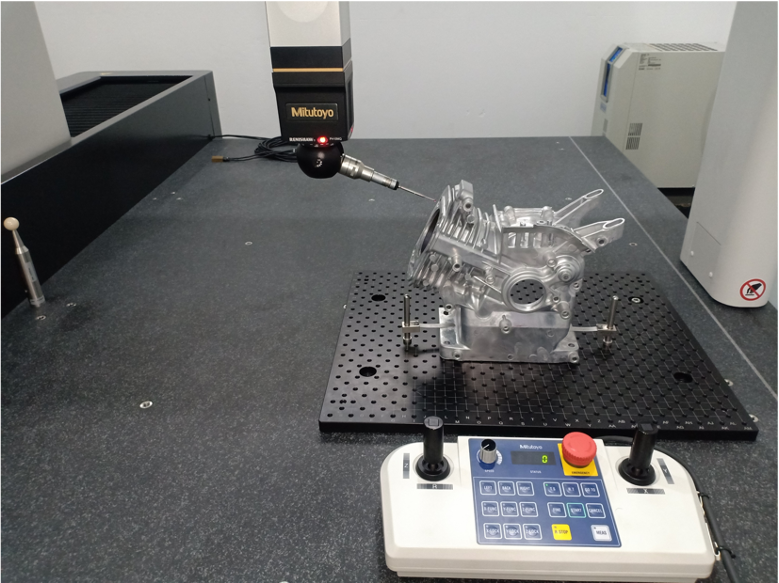

DEFINITION of CMM

CMM also know as Coordinat Measuring Machine is a multi-functional measurement tool, for measuring the geometry of physical objek, by touching the surface of the object with probe sensor that provide the outputs of measurement with high accuracy and efficiency.

ADVANTAGES of CMM

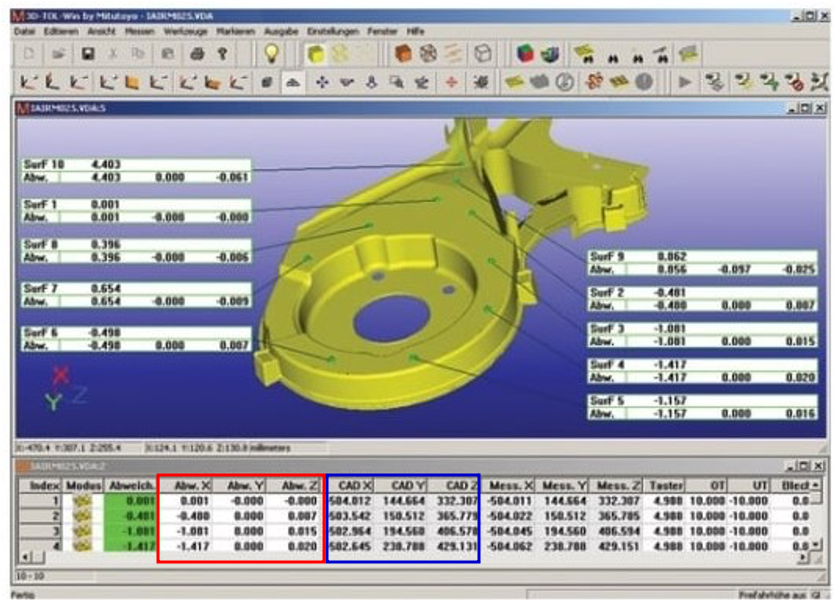

- The measurement results has high precision and accuracy.

- Various character of measurement can be measured such as Flatness, Straightness, Roundneess, Cylidricity, Angularity, Profile Surface, etc.

- Result of measurement data, can be obtained faster and can be printed immediately.

MEASUREMENT COST

Measurement cost is calculate by considering the following points :

- The number of points that measured.

- Quantity of part that measured

- Total time required for measurement.

- Size of part that measured, etc